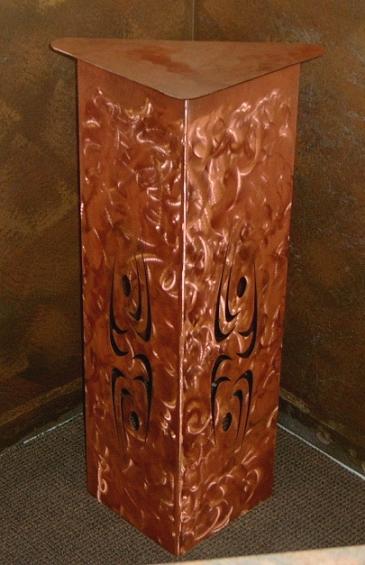

Home | "How To" Demos | Picture Gallery | Contact Info | Store Locations | Links Description Our copper plating solution plates steel and non-stainless steel alloys at room temperature without the need for any special equipment.This unique formula can be applied by immersion,spray or by brush for detailed areas. The two mil thick plating produces a bright,shiny copper finish similar to the appearance of a new penny straight from the mint! The color of the plated surface may be further altered by using our Rainbow Torch or Pewters. After plating and/or coloring, finished parts may be quick dried and sealed, or allowed to oxidize. Oxidation will alter the colors and textures, creating an additional palate of finish effects. The end results that may be achieved are limited only by your own imagination and artistic ability. This solution is the basic building block for an unlimited range of beautiful, interesting looks never before available to steel finishers. |

Primary use

Secondary use

Application Method

For best results, steel being plated must be completely clean and free from all oils, mil plate, rust and any other contaminants. Wear latex gloves if handling part by hand as finger oils will effect the plate quality. Prep steel by sandblasting, pickling, grinding, wire brushing or sanding. Copper Plate will work on uncleaned steel, but uneven plating may occur. Remove residual oils and dirt particles with mild detergent in solution. Rinse with water to remove soap residue. Copper Plate may be applied either by spray or immersion, but immersion is recommended for an even plating. Immersion time is normally 1-2 seconds resulting in a bright copper layer. After plating, immediately rinse in a water bath to remove excess plating solution. If desired, apply Rust Arrest to neutralize the chemical residue, allow Rust Arrest to remain for 20 seconds then rinse again. At this point the finished part should be quick dried with compressed air or another method of your choice to avoid oxidation. An alternate technique is to allow part to dry naturally and allow a slight amount of oxidization to form, altering the appearance and texture. Once you dry your project completely, the part must be sealed with an appropriate topcoat such as acrylic sealer, wax, or clear powder coat, otherwise oxidation will eventually result.

Copper Plate can be used in conjunction with our Rainbow Torch, Dark Pewter and Light Pewter to radically alter the final appearance. If using one of these products along with Copper Plate, skip the Rust Arrest step until finished. See appropriate product for application information. Note, our Copper Plate will not patina in the same fashion as real copper.

Basic Instructions

Technical Data

As with all chemicals, wear protective clothing, latex gloves, eye protection and avoid breathing mist. Use adequate ventilation with a chemical respirator when spraying. No known shelf life.

VOC is under 250